Dival Banerjee (Vuecason)

The founder of Vuecason on his process for learning things quickly, dealing with risk, and building the future of prototyping

Welcome to the 4th issue of Master Plan, a series of conversations with deep tech founders doing really hard things.

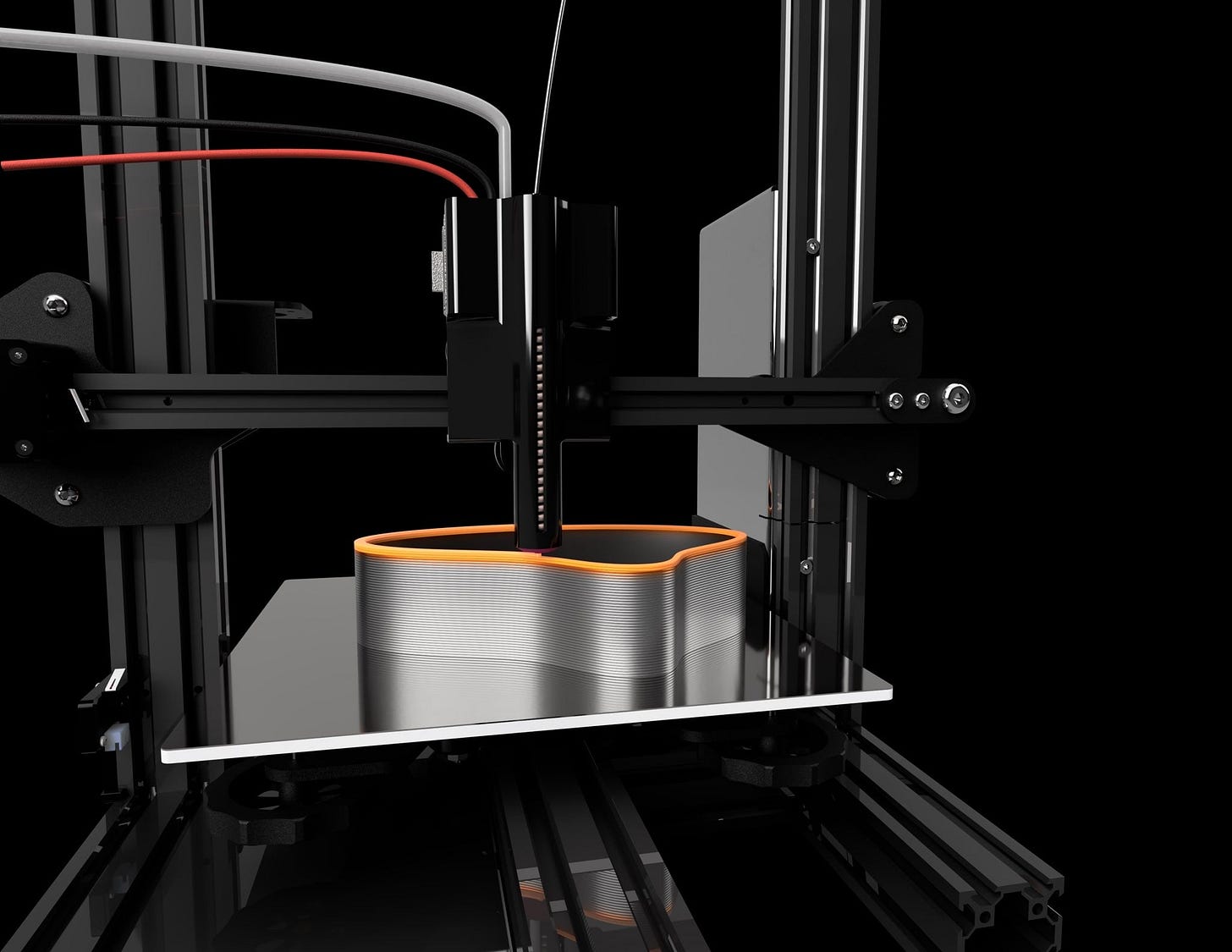

Dival Banerjee is the founder of Vuecason, a company building rapid metal 3D printers. He’s also done work as part of the Hyperloop UC team. We’ll dive into his learning process, thoughts on starting a hard tech company, and how Vuecason is building the future of metal 3D printing.

Dival introduces Vuecason

At Vuecason, we’re building a 3D printer that can print metal through a nozzle, like plastic. We heat and place the metal in one step, which allows us to print large high-performance parts quickly and cheaply.

The one question we’re trying to answer is: how do we make creating physical things more like software? That's the goal. What we want to do eventually is build a high-level manufacturing solution for everyone.

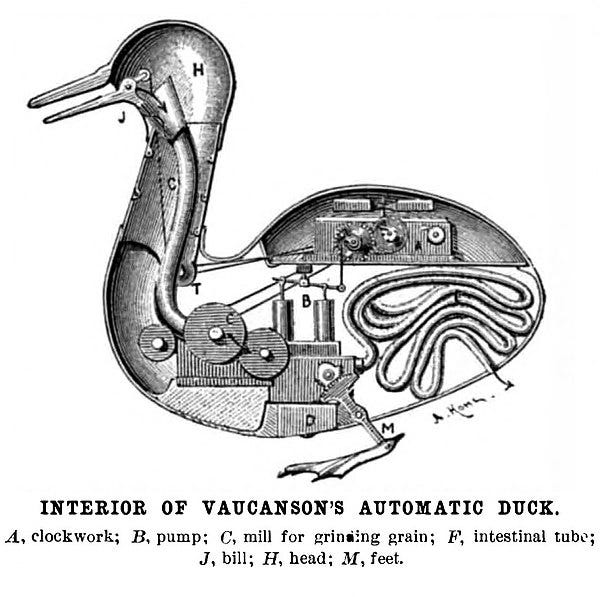

The origins of Vuecason’s name 🦆

Vuecason is a deliberate misspelling of Vaucanson (Jacques de Vaucanson), who invented the metal lathe. However, he’s most known for building something called the digesting duck, which is a robot duck that could seemingly eat food, digest it, and poop it out.

Naming the company Vuecason and making the logo a duck is a way to pay tribute to his work with the metal lathe. Without the lathe, the steam engine wouldn’t exist and the industrial revolution wouldn’t have occurred.

Metal printing still has shortcomings

Let’s compare our product to a binder jet printer, like the one Desktop Metal builds. When you have when you deal with powder—particularly binder jet—it's about how well you can fuse that powder together (which creates a strong part) and how you do it in an even/uniform manner. It takes a ton of simulation to predict shrinkage and thermal stress, so at the moment it’s very difficult to print parts larger than a grapefruit.

If you go the binder jet route with powder, it becomes challenging to achieve the strength and uniformity needed for high-performance parts. I'm sure they'll improve on it over time, but if your customers are in aerospace or tool manufacturing, quite a few of them are gonna care about high-strength, high-performance parts.

Another dominant metal printing technology is direct metal laser sintering (DMLS). A laser fuses layers of metal together in a bed of metal powder. However, these machines are very expensive and require a lot of existing infrastructure to operate. You actually need a cleanroom suit and respirator when cleaning up the finished parts.

DMLS can produce stronger high-quality parts, but the printers require a high upfront capital investment and high operating cost. They’re also too slow to scale for most low volume manufacturing applications.

The Vuecason printer aims to provide high strength, larger part volumes, and shorter lead times per part (if produced sequentially) than binder jet while making sure that the machine is cheaper to operate than both binder jet and DMLS.

On the importance of metal

I think metal will be important, at least for the near term future. Who knows what new materials will exist in 100 years? I don’t—or at least I don’t pretend to know—if metal will be a popular material.

There are some really cool exotic materials that still use metals. I don’t think metal is going anywhere, but we’ll probably see some more things that will look like new metal alloys, or (if we manage to do it cheaply) metal matrix composites.

Carbon fiber is becoming really huge. But even though the cost of carbon fiber is dropping significantly year over year, it’s still very far away from ending up in most things. It’s acceptable for aerospace, though. But there are also lots of difficulties in designing and manufacturing carbon fiber parts as well.

If you want to add more design complexity and slow down iteration, then carbon fiber is the way to go. If you want to speed things up and not think much about manufacturing, then metal printing will let you do that in the future. It won’t let you do that today, but we’re working on it.

On the Lean Startup

I’m not a huge fan of lean startup, because if you do it with hard tech, you’re gonna burn through money really quickly.

The Lean Startup doesn’t really work for hard tech. I think a better approach is going the Zero to One route, where each idea is predicated on a secret very few people agree with you on. Either that or just being really deliberate about what your plan is and really thinking about what your company is going to do. Having that mission and internalizing it is important. You don’t need to follow it exactly, but it’s still useful to think through the details. That way, you’re forced to articulate your own feelings at the very least.

At the same time, you need to move very fast and be ready to pivot and iterate at any time. So there are two important questions you need to ask yourself—what should my plan be, and then how do I set my company up to be as flexible as possible around that plan?

On measuring progress

I follow the Pioneer weekly goal setup where you do a progress update every week about what you’ve done and plan on doing next week. Once I get to the point where the focus is more on iteration and testing, then a lot of it will be more quantifiable, like taking a 3D scan of what’s being printed and comparing the dimensional accuracy to the original part designed on a computer.

In the very early stages, you don’t need to use anything fancy like a Gantt chart. But personally, I definitely need to start using those soon. Vuecason has mostly been a side project up until now, I’m just getting more serious about it. If you want to get super tactical, you can also use things like Long Term Stock Exchange (LTSE) tools to project things like burn rate.

Working on a side project full time is a huge jump. When you’re not working on something full time, it’s not that you can’t make progress, but you can’t completely devote your mind to what you’re working on. And you really want to be thinking about your idea 24/7, in my opinion. I kind of do that already, but it collides with everything else. And now I can focus 100%. That’s extremely helpful.

On motivation

Working on Vuecason is really fun. I enjoy it a lot. I think when you make something you can physically hold or see in real life, that’s really cool. And then when you can program it to move around and do things, that’s even cooler. It’s incredibly euphoric. I can’t even describe it, but it’s definitely a good feeling.

I think you also need to have both strong internal and external motivation. For example, everyone at SpaceX works long hours because they want to go to Mars. That sense of purpose also compels people to work harder at an individual level. If you want your project to be convincing enough to make everyone want to help you, it’s important to give people something bigger that keeps them obsessed.

On risk

Most of the time, the things I build don’t work on the first try. If you want to think of risk from a business perspective, what you’ll find with a lot of hard tech companies is that you don’t have much market risk. If your technology works, you will usually have a market that’s ready for it. So almost all of the risk is technical risk. And I personally think that technical risk is generally easier to navigate than market risk.

With market risk, there are so many unknowns. And with technical risk, you’re governed by the laws of physics, thermodynamics, power, and materials science. If your technology violates that, you know it’s time to work on something else. So in most cases, you kind of already know if your technology is possible or not, and then it’s just a matter of figuring out the few things you need to get there.

One important part of minimizing risk is building the right team. Generally, almost everyone on your team needs to be technical and have complementary skill sets. For example, if you’re building a robotics company and one founder is good at computer engineering, it might be a good idea to have another cofounder that knows mechanical engineering. Some people, like Blake Scholl of Boom, are non-technical but can still put together a team. Elon had a software background but managed to teach himself enough to hire smart people.

Sometimes, you don’t even need to build anything first, and it can be enough to run simulations. In a traditional software product, you have high market risk but the technical risk is much lower because the barriers to entry are lower. More people also want to go the Elon route and start a software company to eventually fund something bigger, but I think it’s better to just work on problems you already care about.

On talking to customers

I think it's always good to talk to customers. Generally, you might not want to try to close sales or secure LOIs right away, but it depends on multiple factors. It’s mostly a question of progress you’ve made at that point. For me, as soon as I have a printhead that works and I’m confident it can do 2D layers, then I can go after LOIs.

That way, I have the confidence to back up what I’m pitching so it doesn’t feel like I’m wasting the customer’s time—I can actually deliver on what I’m trying to sell. Talking to customers is super important. You should at least know what they’re upset about. You don’t need to listen to them all the time, but you should at least be aware of what they’re thinking.

What some of the best companies—the really, really, cool ones—will do is figure out what the customer wants, or what the customer says they want. But then they also know what the customer actually wants but can’t articulate yet. A lot of times, those two things are very different.

Cultural issues with hard tech

A big reason why not as many people are starting hard tech companies is a marketing/PR issue. It’s a perception issue, for sure. People think about deep tech and automatically assume it’s going to be extremely difficult.

But a lot of the problem is also cultural. If you go to school, you’re encouraged to specialize in one area. Maybe it’s engineering, or perhaps it’s the humanities. For the average person, specialization is generally okay, but it doesn’t give people the right skill set for running a company.

If I stuck with the computer engineering route, I would have probably gotten a Master’s in digital signal processing, which is really cool. And it can be helpful. I’d have an excellent career. But having a Master’s in signal processing doesn’t help me in any way if I’m starting a 3D printing company.

If you can combine your interests from multiple fields, especially in tech, that’s best. If you know the basics of a wide range of topics—electrical engineering, computer engineer, software development—and also understand the basics of mechanical engineering, you’re in a really good position to discover lots of opportunities you wouldn’t have realized were there before. You’re able to see where things fall short in each field.

Investment-wise, firms like Lux Capital, Founders Fund, and 1517 Fund are great. Recently, a lot of deep tech investors I see are usually running smaller seed or pre-seed funds. This makes it much easier to get started with fundraising. Deep tech doesn’t go very well with the standard VC model, where they expect you to exit within 5 years. Five years is literally the duration of the fund. If you’re looking for funding, you need investors that are aligned with what you’re building.

Dev tools for the physical world

The software industry is obsessed with dev tools. You see dev tools startups all the time. And it’s awesome because productivity for developers is going up every year. There are always new products to try out as well as all the new problems that come with it.

If you look at the mechanical engineering world, that’s not quite the case. You have CAD programs that let you model whatever you’re designing with a computer, but we don’t have real dev tools for hardware yet. The ones that do exist usually stay proprietary or internal to the company they’re used at. They’re usually not spun out into separate companies or sold as a separate product. And that’s partially because they’re hyper-specialized, but also because that kind of obsession with making engineers more productive isn’t there.

If you have a bit of a software background and you’re aware that dev tools are a real market, why don’t they exist in the mechanical engineering world? That’s when you realize that there’s a huge opportunity to bring some of the software world into the mechanical world.

To learn quickly, skip the fundamentals

Start with what you currently know, then go deep when you encounter problems. Most people would say to start with the fundamentals, but I disagree. This is one area where I’m the exact opposite.

Fundamentals matter, but most people don’t understand them thoroughly without hindsight. For some people, learning the fundamentals upfront works really well, and they’re able to determine when to use which thing. For me, I need to just work on it. It’s also a lot more fun for me that way.

Obviously, you should know the bare minimum of the fundamentals first. I wouldn’t say to learn calculus, but everything up to that you’ll have to know to at least get started. And then it’s really a process of learning how to learn.

If you can learn quickly, you don’t need to rely on the fundamentals. Go ahead and try making something that fails. Try to understand why it fails. If you don’t understand why it failed, that’s a great place to start digging deeper and look for the root cause and figure out what actually went wrong.

Over time, you will learn the fundamentals just by doing work, and often better because you’ll know the context to use each tool. In a physics textbook, you can learn all the laws and equations, but if you notice, most of the problems for each chapter are just small variants of three or four different problem archetypes.

In the real world, many problems are too complex to model compared to the problem archetypes that you’re taught in textbooks. You have to go deeper to get a better understanding.

An example of the process

My recommendation would be to find a way (like an online tutorial) to build what you want to build. After that, figure out ways to improve it.

Let’s say you want to build a drone, and you didn’t learn any of the theory behind how drones work. You didn’t do any calculations, and you didn’t sit through a university course on physics.

Go ahead and build it. Build the drone. And then try to get it to take off and fly. Most likely, it won’t work. The next step is to start asking yourself a ton of questions.

Why isn’t the drone taking off?

It’s going at full throttle, the propeller is spinning, but there’s no lift. Why is that?

Are the motors providing enough thrust?

Is the drone too heavy?

And finally, if you keep Googling random stuff, you’ll eventually come across the idea of thrust-to-weight ratio. And you start to ask yourself: what is the minimum thrust-to-weight ratio needed to let my drone take off?

That’s when you learn the basic physics equations. You’ll realize, “Oh, I have to make sure the force due to thrust has to exceed the force due to gravity to make the drone go up.”

It’s not a hard calculation, but you still need to learn how to calculate that number. You’d end up repeating this process several times for various things, but after lots of mistakes, you’ll have a functioning drone. On the other hand, if you try to learn all the fundamentals, like physics and controls first, you can spend 40 hours reading textbooks and still have no clue what you’re doing.

A lot of times, it’s really important to know when to use something, rather than just how to do it. Using calculus as an example, you don’t need to know how to actually integrate. You just need to know when to use it, then you can throw it in the calculator. You shouldn’t be doing that by hand anyway. You need to know when to use which tool, and the best way to learn that is by applying it in context.

You don’t need a workshop or lab

Having a lab or workshop is not as important as you might think. You could even start a hard tech company from your phone.

It’s highly situational, but for engineering, a lot of the equipment you need can be easily found at online suppliers like McMaster-Carr, or you can order customized parts (like 3D-printed or machined parts) from manufacturers and get them delivered to you.

I think that often, people tend to rationalize themselves out of starting a hardware project because they immediately think about the parts they need to buy to build it. I think you can go far with just designing a project on a computer with CAD software, then running a simulation to evaluate the chances of it working. No lab or physical parts needed on day one.

Now, if you’re doing something like biotech or something research-heavy that must be peer-reviewed, you might actually need a lab.

Lean learning

Hypocritically, the way I learn things looks more like the Lean Startup approach, rather than trying to figure out a deliberate plan. It’s odd to think about, but when it comes to learning things, there are so many things you can’t know from the beginning anyway. Your fundamentals aren’t really fundamentals. They’re just a few things you thought were important.

Sometimes (a lot of times) they actually are important, but with something like metal printing, I did not know everything from day one. I just made a lot of assumptions. And then I spent lots of time trying to figure out if my assumptions were actually correct.

3D printing nuclear reactors

I'm all in on metal printing.

If this printing stuff works out and then 20 years later I want to find something else to do, I either want to get involved in semiconductor fabrication, or nuclear fission. I don’t know anything about either of those industries, but those are good things to focus on.

Metal printing can be used for some parts of nuclear fission reactors. Nuclear reactors are super expensive to build. And as a result of that, you have things like aging reactors, where if you want to replace a part, the supply chain doesn’t exist anymore because the reactor was built 70 years ago.

So the companies that built those parts for you are out of business or typically don’t make that part anymore. And so if you metal print those parts, you can actually cut down on the cost of maintaining existing nuclear reactors. Assuming it meets all the qualifications and certifications, and it’s safe.

Vuecason’s Master Plan

The general idea is to make it easier to prototype things quickly.

When investors think about manufacturing, they only care about speed. But if you talk to customers, most of the time they don’t even know what they want to build.

The plan is to focus entirely on aerospace and tool manufacturers, and what I mean by tool manufacturing or machine tools is the people who design the factory that makes all your products. These industries have the highest leverage for progress in the world of atoms. It’s important that we make it easier to iterate on rockets, aircraft, and the manufacturing lines that make millions of parts a year.

Start with printing titanium

Titanium is the priority, in terms of some of the first materials we want to do. Another alloy I want to do is and tool steel and Inconel. The priority is getting those done. We have to start with those because it’s incredibly difficult to create a new market from scratch. Instead of making things even harder on ourselves, we can start with something where the demand already exists, then push the frontier and expand it outwards.

The Vuecason printer should be able to print any conductive metal in the future. It will take far less R&D to adopt new metals compared to metal printing companies that use proprietary metals.

If we were to jump into manufacturing exotic materials where there might not be a clear market for them, we also end up taking on lots of market risk, which is what we’re trying to avoid in the first place with a hard tech company.

I don’t think printing will change everything, or that you can print every single part. There’s always going to be fundamental limits that you’ll reach eventually with printing. Maybe in the long term, we can get there, but not in the next 10 years.

Build a full-stack prototyping solution

One way to improve production at high volume is to make a 3D printer, and then build the right software on top of it to help automate the design process for your machine tooling.

If you have a product you need to manufacture, we can build a software solution that’s able to figure out which 3D-printed tools you need to manufacture something at X volume per year.

One example is injection molds. You can 3D-print an injection mold and fill it with plastic. And when you do that with 3D printers, there are quite a few advantages you gain from that.

Hopefully, in the long run, metal 3D printing will at least touch every manufacturing process, but I don’t think it will replace all of them.

Declare war on stagnation

For me personally, I’m trying to figure out how to declare war on stagnation, and eventually end it. I want to get rid of every technological reason for stagnation. There are some regulatory reasons I can’t get around, but my goal is to figure out what technology can be built to end stagnation or at the very least eviscerate all perceived stagnation.

If we make making things stupid easy, we’ll have no choice but to make progress as a society. You won’t be able to say that hard tech is hard anymore. It’ll just be regular tech where you can drag your design around on your screen and print it.

We’re very far from it, but the ideal scenario would look like Tony Stark telling Jarvis to change the color of the suit to red or come up with a new alloy, and Jarvis can derive the new part geometry and develop a new alloy on the spot, then manufacture it within five hours. That’s amazing. That’s the vision I’d like to see for prototyping.

At the moment, I don’t actually think metal printing is that useful—even for prototyping. If you prototype a part that needs to be traditionally manufactured on a metal printer, all the physical properties of the part will be different. So the design needs to be changed in order to scale to production.

The plan is to build a machine that can do prototyping, in terms of creating long-term value. And after that, the production version of that machine should use the same type of nozzle and the same type of printing technology, so that when you scale your prototype to production, you won’t need to change anything. The value of prototyping will be much much higher and we can iterate in production much much quicker.

Learn more about Vuecason here.

You can follow Dival on Twitter at @divalbanerjee if you haven’t already. If you want to be notified every time we send out a new interview (we have a few more coming up soon), you can subscribe here. For any questions, feedback, or requests, send them to me via Twitter.